The Importance of THC-A Quality Assurance

In the rapidly expanding cannabis sector, assuring the quality of THC-A products holds utmost significance. Quality assurance ensures products meet established safety and potency standards and plays a pivotal role in fostering consumer trust and protecting public health.

Understanding the Significance of Quality Assurance in THC-A Products

The critical importance of quality assurance in THC-A products cannot be emphasized enough. Quality protocols aim to certify that products are not only effective but also safe for consumers. Through adherence to these stringent standards, the industry can confidently assure consumers that their products meet rigorous quality benchmarks.

Consumer Safety and Trust as Primary Drivers

Safety and trust amongst consumers are the primary motivators behind stringent THC-A quality assurance measures. Ensuring products are devoid of contaminants and labeled accurately for potency and purity helps safeguard consumer health. Consistent and transparent quality practices foster trust, motivating both novice and experienced consumers to confidently select THC-A products.

Impact on the Credibility of the Cannabis Industry

Beyond individual companies, comprehensive quality assurance significantly enhances the credibility of the entire cannabis industry. As consumers become more informed about cannabis products’ benefits and risks, they demand higher standards of quality. Committing to thorough testing procedures and quality protocols helps the cannabis industry boost its reputation, advocate for consumer protections, and cultivate a responsible market environment.

Commitment to THC-A product quality extends beyond compliance; it’s a continuous dedication to excellence and consumer well-being. As the industry progresses, these practices will remain integral to its success and growth.

Step-by-Step THC-A Testing Procedures

Assuring the quality of THC-A products commences with a detailed, step-by-step testing procedure devised to uphold the highest standards in the cannabis industry. Here’s an exhaustive look into how these procedures are meticulously carried out.

Overview of Standard Testing Protocols

Standard testing protocols are the cornerstone of quality assurance in THC-A products. These protocols are methodically formulated to ensure the consistency, safety, and efficacy of the products. Each batch undergoes several testing phases to validate adherence to predefined standards and regulatory mandates.

Detailed Explanation of Each Stage: From Cultivation to Finished Product

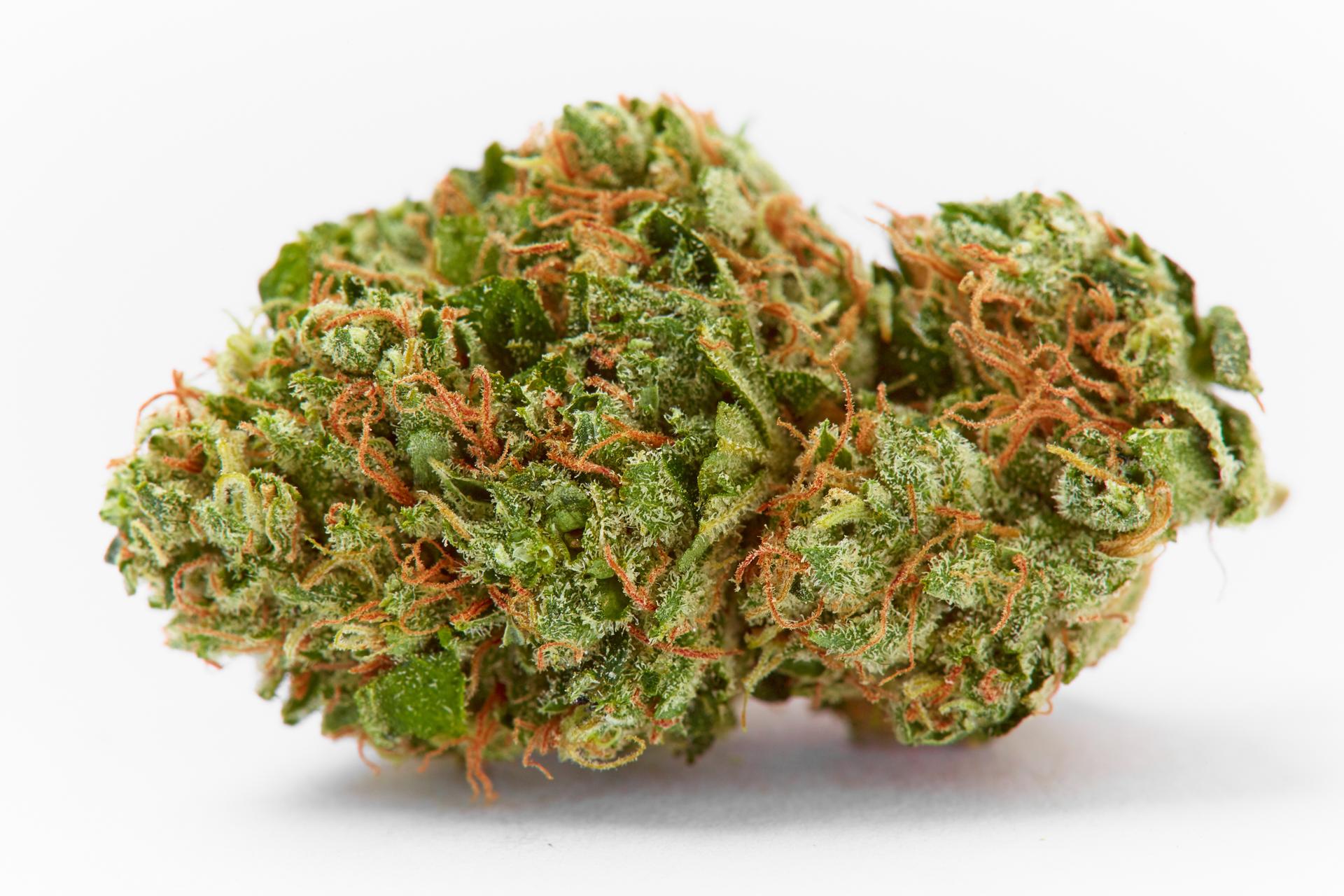

The testing journey begins at the cultivation stage, where soil quality, water sources, and plant health are scrutinized. Samples are gathered throughout various growth stages to assess levels of THC-A and other cannabinoids, aiding in early problem detection and mitigation.

Once harvested, raw cannabis undergoes stringent tests, including microbial analysis to detect harmful bacteria or fungi, and screenings for pesticides and heavy metals to ensure contamination-free products. This is followed by rigorous potency testing to measure THC-A content, aligning with consumer expectations and legal standards.

Extracted oils and concentrates also undergo purity and potency testing. Advanced chromatography techniques isolate and measure extract components, ensuring the final product is potent and pure, with additional stability and consistency checks conducted before packaging.

Types of Tests Performed: Potency, Purity, and Contaminants

Several types of tests are performed on THC-A products to ensure quality:

- Potency Testing: Measures THC-A concentration in a sample. High-Performance Liquid Chromatography (HPLC) is commonly used.

- Purity Testing: Ensures the product is free from unwanted compounds or adulterants, crucial for safety and efficacy.

- Contaminant Testing: Checks for microbial contaminants, pesticides, heavy metals, and solvents, ensuring these are below harmful levels essential for consumer safety.

By adhering to these rigorous testing procedures, producers in the United States can provide consumers with high-quality, safe, and effective THC-A products, fostering trust and confidence in the cannabis industry.

Role of Sustainable Cultivation in Quality

Implementing sustainable cultivation practices profoundly impacts the overall quality of THC-A products. Central to these practices is a dedication to preserving the environment while ensuring that the end product meets the highest quality standards.

How Sustainable Practices Contribute to Product Quality

Sustainable cultivation techniques prioritize the holistic health of cannabis plants, from soil health to water usage and pest management. Through promoting biodiversity and utilizing natural inputs, growers produce more resilient and potent plants. This not only enhances THC-A quality and purity but ensures products are free from harmful chemicals and contaminants.

Overview of Environmentally Friendly Cultivation Techniques

Eco-friendly cultivation methods include organic farming, natural pest control through beneficial insects, and water conservation practices such as drip irrigation. Additionally, using renewable energy sources and reducing carbon footprints with efficient logistics supports sustainability.

Practices like crop rotation, companion planting, and using organic fertilizers contribute to healthier soil and plants, enhancing THC-A products’ cannabinoid profile and ensuring consistency in potency and efficacy.

Long-term Benefits of Sustainable Practices for Both Consumers and Producers

Consumers benefit from sustainably cultivated THC-A products, offering peace of mind with products derived from environmentally responsible methods. These practices reduce synthetic pesticides and chemical exposure risks, providing safer consumption options.

Producers adopting sustainable practices benefit from long-term soil fertility and healthier crops, potentially leading to better yields and higher quality produce. Furthermore, sustainability aligns with the growing consumer demand for eco-friendly products, helping brands cultivate trust and loyalty.

In conclusion, sustainable cultivation is both an ethical choice and a crucial aspect of producing high-quality THC-A products. These practices cater to consumer health and wellness while respecting the environment.

Expert Production Techniques: Ensuring the Best THC-A

Producing top-quality THC-A begins with expertise and specialized knowledge. Simply growing cannabis isn’t enough; superior THC-A production demands a profound understanding of plant biology, extraction processes intricacies, and the integration of scientific advancements into practice. Experts in the field bring essential knowledge, ensuring each step, from cultivation to the final product, adheres to strict quality standards.

Specialized equipment and methodologies form another cornerstone of exceptional THC-A production. Advanced technology like high-performance liquid chromatography (HPLC) precisely measures cannabinoid levels, ensuring potency and purity. Additionally, state-of-the-art extraction equipment maximizes yield while preserving THC-A integrity. These tools offer precise control over the production process, resulting in products that are effective and safe for consumers.

Continuous improvement and innovation are key to sustaining excellence in THC-A production. Producers continually seek new methods and technologies to enhance quality and efficiency, such as adopting novel extraction techniques, implementing more rigorous testing protocols, or exploring sustainable practices benefiting both the environment and consumers. Remaining at the industry’s cutting edge helps producers maintain high standards and consistently offer products that meet an informed, discerning audience’s expectations.